Units

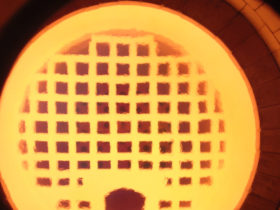

Sulfur Recovery Units

The sulfur team at Principal Technology has over three decades of design, fabrication, and operations support for all aspects of traditional modified-Claus Sulfur Recovery Units including modular and stick-built fabrication and construction, tail gas treating, thermal oxidizers, degassing, and storage and handling facilities. Our SRU portfolio includes over 2,000 LTPD combined nameplate capacity with over 11 Million Long Tons of Sulfur Recovered to date.

The sulfur recovery options for most gas producers and refinery applications are very well suited to traditional Modified-Claus Sulfur Recovery Units. Depending on your operations and permit requirements, an enhanced SRU (e.g., Selective Oxidation, Cold Bed Absorption – CBA) may be all that is required. For new unit construction or significant revamp, a Three-Bed Claus unit coupled with a Tail Gas Unit (e.g., amine-based or caustic scrubbing) will provide exceptional recovery efficiency with residual total sulfur compounds in your plant effluent of less than 250 PPM.

Our project portfolio includes modular and stick-built construction of Sulfur Recovery Units and Tail Gas Treaters ranging from 2 LTPD to multi-train 500 LTPD facilities and H2S feed concentrations from 10-90%. See our Units webpage on Small Capacity Sulfur Units for specific information about units operating under 20 LTPD.

Our design team can support your project from feasibility and technology selection, detailed design, design-build, start-up support, training, ongoing operations consulting – and anything in between.

Contact our team today to discuss your Sulfur project needs.