Units

Oxygen Enrichment Systems

The nature of the Modified-Claus process requires the combustion of a portion of the incoming Acid Gas Feed along with all ammonia and hydrocarbons present in the feed. This process requires oxygen from combustion air, and the nitrogen in that air comes along for the ride.

An easy way to improve unit capacity is to remove nitrogen from the unit by enriching the combustion air with pure oxygen.

SRUs are the final processing unit in refineries and gas plants and are designed to operate at relatively low pressures. Because of these operating constraints, SRU maximum throughput is limited by pressure drop through unit equipment for a given feed. Downstream Tail Gas Units and Thermal Oxidizing equipment can further increase pressure drop and further limit throughput.

The Modified-Claus SRU process gas leaving the Thermal Reactor will contain between 40-60% nitrogen depending on feed H2S and hydrocarbon concentration, and if the SRU is also processing ammonia-laden Sour Water Acid Gas.

With this large fraction of inert nitrogen doing little more than taking up valuable space in your unit, it is easy to see why Oxygen Enrichment of your Combustion Air stream is seen as a silver bullet to increasing SRU capacity without replacing your primary equipment.

To a significant degree, this approach accomplishes this goal, but it cannot be haphazardly implemented. Beyond the inherent hazards that must be addressed in your oxygen handling system design, including metallurgy, velocity, impingement, pressure drop, and safety control system design requirements – Your SRU requires careful attention to this new operating philosophy:

- Combustion Air System Metallurgy – Depending on the level of Oxygen Enrichment required, many plants will be able to use their existing carbon steel SRU combustion air piping reliably. The location and design of your oxygen injection to this stream must be carefully considered to prevent forming any additional hazards from localized high-concentration or high-velocity oxygen streams. For units operating under high levels of enrichment, this piping may require a metallurgy upgrade.

- SRU Process Burner – Your SRU burner will likely require a replacement or at least some modification. In many burner systems, combustion air provides the necessary cooling of the burner internals. Reducing the air flow rate relative to the feed rate and Thermal Reactor temperature should be considered as part of your Oxygen Enrichment system design.

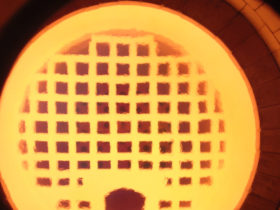

- Temperature Management and Refractory – The one function that nitrogen does perform in a traditional SRU is acting as a diluent that effectively attenuates the maximum temperature potential for your thermal reactor. Once oxygen enrichment is used, the potential maximum temperature for your system increases significantly during both normal operation and process upsets. The normal operating temperature also increases proportionally. The Refractory system in your thermal reactor may need to be upgraded.

- Boilers, Condensers, and Heat Exchangers – Much like the increased temperature of the Thermal Reactor, your heat transfer equipment needs to be evaluated to ensure it can handle the increased gas temperatures and that your condensers and condenser plenums can accommodate the increased sulfur load. Upgraded tube sheet refractory and entrained sulfur separators will need to be considered.

Contact us to discuss your SRU capacity challenges and to determine if Oxygen Enrichment is the right technology for your plant. PTI’s experienced team is ready to help with process and hazard evaluations, operator training, and equipment consulting through complete detailed design or design-build services.