Specialty Equipment

Sulfur Complex Burner Management Systems

PTI's engineers have over three decades of design-build experience with specialty safety control and burner management systems for Sulfur Recovery Units, Tail Gas Treating, Thermal Oxidizers, and Incinerators.

Like most critical elements in the Sulfur Block, process safety and burner management systems are unique. PTI's team has the expertise to apply industry standards and unit-specific know-how to design, build, and train your operators on the specialty systems used to operate these vital units in your facility.

A typical Sulfur Complex contains multiple burner management and combustion control systems. These systems can be integrated into an existing plant safety system or be dedicated, stand-alone safety controllers.

Unlike a typical furnace or fired heater BMS, a sulfur unit safety system must tightly integrate with the process controller to allow a smooth transition from pre-ignition purge and start-up to normal operation and finally shut down. This tight integration is critical to managing stoichiometric combustion during all phases of the unit operation.

Most industrial standards do not directly apply to a sulfur unit BMS, or they apply with slight modifications. The team of engineers at PTI has developed our design standards utilizing a variety of industry standards, including:

- National Fire Protection Association, NFPA, Standard 86 for Ovens and Furnaces including Special Atmospheres.

- International Society of Automation, S84

- International Electrotechnical Commission, IEC 61508 – Electrical Functional Safety

- IEC 61511- Functional Safety

In addition to incorporating these industrial standards, PTI engineers are involved with the upcoming API 565 Thermal Reactors for Sulfur Recovery Units in General Refinery Services.

Beyond the safety logic solver and functional safety of an SRU BMS, PTI incorporates the following design elements to provide maximum onstream time, minimizing nuisance shutdowns without compromising the performance of the safety system.

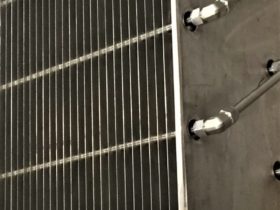

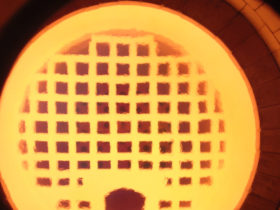

- High-Intensity Premixed Natural Gas Pilot, Designed for Continuous Exposure to the High Temperatures and Aggressive Environment of an SRU Thermal Reactor.

- Pilot Cooling Purge System with optional Retractable Pilot Assembly

- Redundant, Dual Frequency Optical Flame Scanners to protect from UV wavelength attenuation in acid gas service.

- Inert Gas Pre-Ignition Purge Flow Systems

- Double Block Fuel Trains

- Automatic Switching Air : Nitrogen Purge Systems

- Cooling and Sweep Purges for all Critical Instruments

Our team applies these same design standards for Thermal Oxidizers and Incinerators modified to meet the specific needs of natural draft stack-based incinerators or forced draft, positive pressure Thermal Oxidizers with waste heat recovery boilers.

Contact our team to discuss your Sulfur Complex burner management system.

related Specialty Equipment

Amine Filtration Systems

Electric Process Gas Heaters for Sulfur Recovery Units

Entrained Sulfur Removal Elements – Heated ESRE™

Hazardous Area Gas Monitoring

Low-Pressure Rich Amine Flash Drums (RAFD)

SRU Modified-Claus Process Burners

SRU Tail Gas Diverter Valves

Sulfur Facility Process Safety and Control Systems

Sulfur Handling & Degassing