Specialty Equipment

SRU Modified-Claus Process Burners

Acid gas burners are the heart of any SRU. Thorough mixing of air and acid gas results in short, high-intensity flames and high combustion temperatures, setting the stage for the rest of the SRU to complete its mission of maximum recovery.

PTI's SRU Burners accomplish this with a specialty-designed tangential air stream and high-velocity radial gas injection barrel. When coupled with our purge and burner management systems - PTI burners provide reliable long-term SRU operation.

PTI’s specialty-designed Sulfur Recovery Burners are ideal for new or retrofit and replacement projects using conventional combustion air or Oxygen Enriched air streams. Our SRU Burners enhance mixing, extend burner life, provide thermal radiation control, and extend the broad operating range for high turndown ratios.

When coupled with our Burner Management Safety Systems designed to detect both the pilot and the main flame and our automated purging system to keep viewing windows and instrument nozzles cool and free of soot and debris, the PTI SRU burner system provides reliable operation through all regimes of SRU operation while minimizing nuisance trips and unnecessary shutdowns.

Our SRU Burner design elements meet stringent industry standards and address the most common problems with legacy SRU Burners.

Mechanical Construction:

- ASME Section VIII Vessel Code Design

- Post-Weld Heat Treated Carbon Steel Nozzles and Shell Components with High-Alloy and Stainless Steel Internals

- Typical 150# Flange rating with available design pressures from 20-50 PSIG and design temperatures ranging from 350°F to 600°F to align with the most demanding standards used by our clients.

- Our Wide-Eye(TM) close-coupled sight port provides a 25% improvement in the field of view for the SRU Thermal Reactor checker wall and Boiler tube sheet. To provide online repair and replacement, we equip our site ports with a low-profile knife gate valve for isolation.

- By eliminating cantilevered members inside the burner, our design significantly reduces vibration from damaging resonant frequencies.

- Three pad-style flanged inspection ports at every 120° on the Acid Gas Plenum.

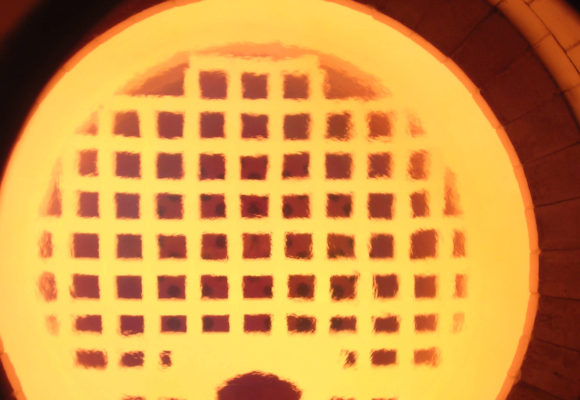

- Custom-cast and pre-fired burner tiles provide the final element in controlling the flame shape and improving mixing of the process gases as they enter the SRU Thermal Reactor.

- High-intensity pre-mixed pilot designed for reliable operation in the pressurized furnace of an SRU Thermal Reactor. Our automatic purge cooling system allows the pilot to remain in place even when the pilot is off. We also offer an optional retractable pilot design.

- Dual mode, redundant flame detectors carefully aligned to separately see the pilot flame and the SRU Burner main flame. PTI utilizes laser alignment fixtures for the flame scanner ports during burner fabrication which eliminates the challenge and frustration of ball-style adjustable scanner ports, which can easily be knocked out of place, causing nuisance shutdowns and operator headaches.

Process Design:

- Mixing, Mixing, Mixing… The single most important consideration for an SRU Burner is efficient mixing to allow the front chamber of the Thermal Reactor to fully combust and react both the H2S required for the Modified-Claus process and any spurious ammonia and hydrocarbons that are along for the ride from your upstream units.

Our design engineers utilize our Integrated Vector™ approach to accomplish superior mixing. This approach incorporates an induced tangential vector in the combustion air flow stream coupled with point-focused, radial high-velocity jets for natural gas, sour water, and amine acid gases.

- Wide Turndown – PTI design engineers optimize acid gas jet sizing and the combustion air barrel to provide the inherent capability to operate efficiently across a wide range of acid gas feed rates and compositions.

- Temperature Management – Radiation is a significant component of the heat absorbed by any burner in Sulfur service. PTI’s SRU Burner design incorporates parabolic radiation shields to protect both burner internals and the burner shell from high SRU operating temperatures.

- Drainage and Condensate Protection – Acid gas conditioning with properly designed knock-out drums and pipe heat tracing can eliminate liquid carry over to an SRU burner, but mixing saturated process streams creates the potential for condensate formation near or in the SRU Burner. Left unchecked, this condensate will flash and damage burner internals. PTI’s burner design incorporates a multi-chambered drain system and “shot-pot” allow operators to protect your burner by easily collecting and returning this condensate to your sour water system.

Contact us to discuss your SRU Burner project with one of our experienced sulfur experts.

related Specialty Equipment

Amine Filtration Systems

Electric Process Gas Heaters for Sulfur Recovery Units

Entrained Sulfur Removal Elements – Heated ESRE™

Hazardous Area Gas Monitoring

Low-Pressure Rich Amine Flash Drums (RAFD)

SRU Tail Gas Diverter Valves

Sulfur Complex Burner Management Systems

Sulfur Facility Process Safety and Control Systems

Sulfur Handling & Degassing