Specialty Equipment

Low-Pressure Rich Amine Flash Drums (RAFD)

We use the maxim that "Everything wrong with your Sulfur Unit can be blamed on your Amine Unit". While all of the units in a Sulfur Facility have unique design and operating challenges, this statement often holds true.

A well-designed low-pressure Rich Amine Flash Drum can provide a cost-effective "safety net" to help prevent process upsets from wreaking havoc on your SRU. PTI's RAFD system design minimizes hydrocarbon carryover and normalizes SRU feed streams.

Troublesome Rich Amine solutions, typically, are an amalgamation of multiple liquids, dissolved process gases, and undesirable foams, solids, and contaminants. Proper amine filtration and process design can minimize the unwanted solids, but dissolved gases from high-pressure contactors and liquid hydrocarbons will flash in your Amine Regenerator. These compounds travel straight to your Sulfur Unit, where they cause significant air control upsets throwing off conversion and forming soot that fouls boiler and condenser tubes and catalyst beds, leading to shortened run times. Large slugs of hydrocarbons can make their way to the Thermal Oxidizer / Incinerator and cause high-temperature trips and unit shutdowns.

Low-Pressure Rich Amine Flash Drums stabilize the feed to your Amine Regenerator and Sulfur Unit by separating liquid hydrocarbons and flashing light hydrocarbons from Rich Amine before it reaches your Amine Regenerator. The key elements we include in our RAFD system design are:

- A minimum 30-minute rich amine residence time – Sacrificing residence time to save cost on a smaller vessel defeats the purpose of a RAFD by failing to provide adequate liquid hydrocarbon separation time and normalizing the rich amine feed to your Regenerator.

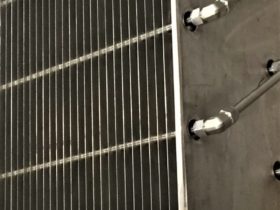

- Three-chambered weir-over-weir drum design to separate liquid hydrocarbons that can be reclaimed in your slop oil system.

- Low-Pressure Operation – We target under 5 PSIG or less RAFD operation to flash off lighter hydrocarbons. Operating a RAFD at a typical 50 PSIG may eliminate the need for rich amine pumps but prevents light hydrocarbons from flashing and ultimately carrying over to your SRU.

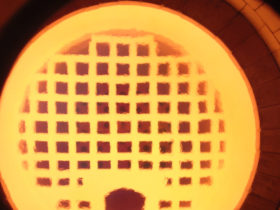

- Top-Hat Wash Column – By incorporating a top-hat style wash column on your RAFD, any H2S that may evolve in the flashed vapor is efficiently recaptured and returned to the system. A small stream of lean amine and a manually adjusted rotameter is all that are required to control and capture entrained H2S in your RAFD vent stream. The scrubbed vent will not impact sulfur loading in your flare or vapor recovery system.

- Rich Amine Pumps – Accomplishing a low-pressure flash requires pumps to return the rich amine to your Amine Regenerator. Our standard design incorporates double mechanical seals and an API 52 seal plan to maximize the integrity of Rich Amine pump process seals.

- Slop Oil Pump – Normally, only one slop oil pump is needed to return collected material to the slop oil system. If required, a spare pump can be provided.

Contact PTI’s team today to discuss upgrading your Amine Unit with a low-pressure Rich Amine Flash Drum. Our engineers and designers can design or design-build your RAFD system in modular, stick-built, or a hybrid form-factor to optimize layout and minimize your construction downtime.

related Specialty Equipment

Amine Filtration Systems

Electric Process Gas Heaters for Sulfur Recovery Units

Entrained Sulfur Removal Elements – Heated ESRE™

Hazardous Area Gas Monitoring

SRU Modified-Claus Process Burners

SRU Tail Gas Diverter Valves

Sulfur Complex Burner Management Systems

Sulfur Facility Process Safety and Control Systems

Sulfur Handling & Degassing