Specialty Equipment

Air-Nitrogen Automated Purge Systems

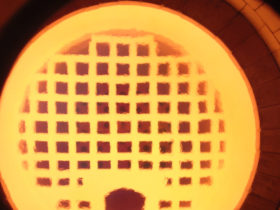

The auto-ignition of molten sulfur and design of a modified-Claus SRU requires operators prevent excess oxygen from flowing through the unit. Temperature excursions and sulfur fires can be common if excess air enters an SRU.

Using nitrogen for nozzle purges, pre-ignition purge, and thermal reactor nozzle cooling is a simple solution. Nitrogen, however, can be a costly utility. Contact our design team to discuss how an automatic air/nitrogen purge system can minimize your nitrogen consumption.

Molten sulfur has an auto-ignition temperature of only 450°F. Additionally, pyrophoric iron sulfide can be present on most of the piping and equipment surfaces in an SRU. Since all SRUs can suffer from residual molten sulfur that lays down on catalyst beds, in condenser plenums, and piping, operators must be diligent in controlling the introduction of air to the unit.

During controlled shutdowns, much of this molten sulfur migrates to the condenser plenums and drains from the unit. But even the most industrious operator will not be able to remove it all. An SRU must be kept under an inert environment until it is cooled and passivated.

The harsh and fouling nature of the sulfur process requires purging most instrument nozzles in addition to using an inert gas flow to purge the unit before burner ignition.

Some clever designers of legacy SRUs attempted to address this challenge by installing start-up vents that could use air for the pre-ignition purge cycle and flip back to the normal flow path once the unit was under stoichiometric control. On paper, this is a feasible solution, but in reality, the harsh duty of a sulfur unit takes its toll on actuated valves in this service. The end result creates a maintenance headache for operators to maintain these mechanical systems.

Nitrogen is the most readily available inert gas available for this purpose. However, like most utilities, it is not free.

PTI’s design approach captures the best of both worlds. Our purge systems utilize air for 80+% of the SRU operation when the control system can accommodate the excess air, then automatically switch to nitrogen for pre-ignition purge and when required to protect the unit from latent sulfur fires.

Contact our project team today to discuss upgrading your legacy SRU to a modern N2+IA purge system.

related Specialty Equipment

Electric Process Gas Heaters for Sulfur Recovery Units

Entrained Sulfur Removal Elements – Heated ESRE™

Hazardous Area Gas Monitoring

Low-Pressure Rich Amine Flash Drums (RAFD)

SRU Modified-Claus Process Burners

SRU Tail Gas Diverter Valves

Sulfur Complex Burner Management Systems

Sulfur Facility Process Safety and Control Systems

Sulfur Handling & Degassing